Before replacing a powdered ingredient in a snack application, our client wanted to be sure that their chosen new material would behave in a similar way during storage and processing – with no detrimental impact on the manufacturing process or product shelf life.

As the new powder would be stored in large silos prior to use and hoppers during production, we designed an analytical study to understand whether certain environmental conditions would drive agglomeration and caking.

We placed a series of snack concepts and the existing snack product in stability cabinets for a defined period of time. Temperature and relative humidity conditions were set to replicate those that might occur during storage and manufacturing.

At four time points, we removed the snack concepts to carry out two types of analysis:

Shelf life

Water activity in all test concepts, at every timepoint, was below the 0.600 a/W threshold at which fungal growth begins; indicating that use of the new material would achieve a similar product shelf life as the existing powder.

Powder flow

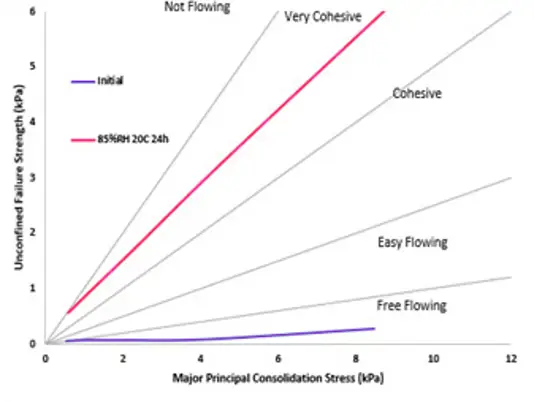

Initial test data showed a comparable performance, with all powders found to be cohesive under low stress and free flowing under increasing stress levels. (See figure 1)

Storage

Elevated relative humidity (85%), even for short periods at low temperature (20◦C), demonstrated the hygroscopic nature of the materials and revealed limits of safe exposure for storage and production.