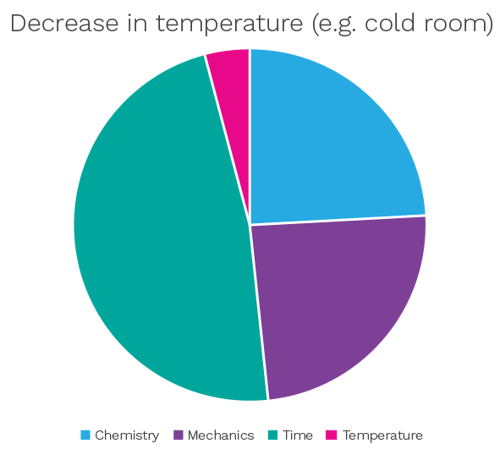

Hence, the classic Sinner approach informs us that chemistry / chemicals, mechanical power / wiping, time (especially contact time) and temperature (especially decreases in temperature) each represent the four essential factors that determine the success of both cleaning and disinfection.

Working through the Sinner Circle approach with personnel who perform either cleaning or disinfection can represent a useful training aid.

The requirements of the Sinner Circle can be enhanced. Researchers Wilson and colleagues (2) and Fryer and Asteriadou (3) have proposed adaptations. Factors to add include

- Flow of water / cleaning agents (this is of importance to C-I-P units)

- Type of soiling

- Amount of soiling

- Condition of soiling and other deposits

- Surface type

- Surface roughness

- Surface condition (especially irregular topographies) (4)

To this, I think the time that soiling has been in contact with the surface and the microbial factors can be added:

- Type of microorganisms

- Number of microorganisms

- Time of contact

- Probability of biofilm formation

Each of these are factors independent of the cleaning agent or disinfectant. Another important consideration is people.

This leads to a modified representation of the important considerations for cleaning and disinfection, which can be represented as Figure 6.

Figure 6: Sandle's representation to the essential factors for cleaning

Figure 6 can only present a broad overview. Within each area, further details will no doubt be required. With design, for example, the dimensions and spatial area of the item to be cleaned are of great importance, both in terms of cleanability and to assess the quantity of cleaning chemicals required and the time anticipated for the cleaning to take. Time is also dependent upon the method of cleaning and the expected level and type of contamination.

A related area of importance is when approaching something that is new for cleaning or disinfecting. Here the following schematic (Figure 7) may be useful:

Figure 7: Key questions to consider when designing a new cleaning process

Not every point included in Figure 7 will be required for every scenario and there will be differences between cleaning a new item of equipment to disinfecting a modified cleanroom. In addition, the level of detail required for each scenario will vary and as such different types of models are appropriate for different situations. Generally, data inputs are needed, such as how ‘clean’ is to be assessed (e.g., visually, based on conductivity, based on carbon or tests for a specific substrate). This leads to decisions relating to test methods and the level of test sensitivity required, as well as how samples are to be taken (especially surface samples, rinse samples, or the general combination thereof). Where microbial concern is a feature, separate tests to estimate microbial numbers or the presence of microbial toxins will be required.

In some cases, the standard swab and rinse sampling are sufficient to assess pre- and post-cleanliness levels. However, it may be that more sophisticated measurements are required, prompting the use of methods like atomic force microscopy, quartz crystal microbalance, optical profilometry, micromanipulation, millimanipulation, fluid dynamic gauging and chemical mapping (using infrared spectroscopy or X-ray spectroscopy) (e.g., Whitehead et al., 2011) or for microbial fouling and biofilms, differential staining.